UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE

SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 27, 2008

Commission file number 0-21835

SUN HYDRAULICS CORPORATION

(Exact Name of Registration as Specified in its Charter)

| Florida | 59-2754337 | |

| (State or Other Jurisdiction of Incorporation or Organization) |

(I.R.S. Employer Identification No.) |

| 1500 West University Parkway Sarasota, Florida |

34243 | |

| (Address of Principal Executive Offices) | (Zip Code) |

941/362-1200

(Registrant’s Telephone Number, Including Area Code)

Securities registered pursuant to Section 12(b) of the Act

| Title of Each Class |

Name of each exchange on which registered | |

| Common Stock $.001 Par Value | NASDAQ Stock Market, LLC |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes ¨ No x

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer | ¨ | Accelerated filer | x | |||

| Non-accelerated filer | ¨ | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

The aggregate market value of the shares of voting common stock held by non-affiliates of the Registrant, computed by reference to the closing sales price of such shares on the Nasdaq Stock Market, LLC, as of the last business day of the Registrant’s most recently completed second fiscal quarter was $381,777,690.

As of February 27, 2009, there were 16,664,653 shares of common stock outstanding.

PART I

ITEM 1. BUSINESS

Overview

Sun Hydraulics (the “Company” or “We”) designs and manufactures screw-in hydraulic cartridge valves, manifolds and integrated packages for sale to international markets. These products are integral parts of hydraulic systems and are used by a variety of capital goods equipment manufacturers to control force, speed and motion.

The cartridge valves Sun Hydraulics produces are differentiated in the marketplace by their floating design. This design methodology provides benefits which include, but are not limited to, enhanced capacity, higher reliability, higher operating pressure capability, reduced size and greater installation flexibility. All of these benefits translate to the Company’s manifold and integrated package offerings.

The breadth and scope of Sun Hydraulics’ product offering is unparalleled in its industry. The Company believes this wide and diverse product offering acts as a barrier to entry for new competitors.

Sun Hydraulics’ products are used by a wide range of industries, most of which are considered capital goods producers. Product sales are broadly segmented by whether the product is used in a mobile or an industrial application. (see Products) Sun Hydraulics’ products are general purpose devices designed for use by a broad market. To a limited degree, the Company has designed specific products to a single customer’s specification.

The Company has operations in the United States, England, Germany, France, Korea, China and India (the Chinese operation is a joint venture and the Indian operation is contractual). Products are sold primarily through independent authorized distributors who often act as system integrators by supplying complete hydraulic systems to OEMs. Sun Hydraulics’ foreign operations sometimes deal directly with customers in addition to managing independent distributors in their respective geographic regions.

In 2008, 47% of consolidated sales went to customers in the Americas, 34% to customers in Europe, the Middle East and Africa, and 19% to customers in the Asia/Pacific Region. In 2008, sales to any single customer or distributor did not exceed 7%.

Sun Hydraulics attributes its success to the innovative design and diversity of its products, the consistent high quality of its products and services, its ability to reliably deliver products on time, the breadth and diversity of its end markets, its geographic presence and the brand recognition of its products. The Company has been profitable every year since 1972 and has paid a dividend every quarter since going public in January 1997.

The Company was organized as a Florida corporation in 1986 to take over the operations of the business of the Company’s predecessor, Suninco, Inc. (f/k/a Sun Hydraulics Corporation). Suninco, Inc. was founded in 1970. The Company’s executive offices are located at 1500 West University Parkway, Sarasota, Florida 34243, and its telephone number is (941) 362-1200. The Company’s website is www.sunhydraulics.com.

Industry Background

Sun Hydraulics is part of the hydraulics industry. Hydraulics is a form of fluid power that is used to achieve power transmission and motion control. Due to its mechanical advantage, hydraulics is widely employed to move and position materials, control machines, vehicles and equipment, and improve industrial efficiency and productivity. The primary products produced by this industry include; pumps, used to create the flow of fluids, valves, used to direct the flow and control pressure and the rate of flow, and actuators, which convert energy to work. The industry also produces other products including hose, fittings, sensors, accumulators, filters, regulators, lubricants, fluids and other items. The industry, in its present form, developed in the 1940s and 1950s.

Screw-in hydraulic cartridge valves provide a more desirable alternative to conventional forms of hydraulic valves. Conventional hydraulic valves are generally large, typically manufactured from iron castings,

2

limited in their interface flexibility and usually designed to control a single task. Screw-in cartridge valves provide the same functional characteristics as conventional valves, but in a smaller size and often at a smaller cost. They are made from machined steel parts, are lighter-weight and more compact than conventional valves and provide significant advantages in interface flexibility.

These advantages help screw-in cartridge valves to displace conventional valves. Hydraulic system design engineers are able to develop complete control systems with multiple screw-in cartridge valves grouped together in a manifold to create an integrated package (i.e. a hydraulic control system functionally analogous to an electronic integrated circuit). Integrated packages optimize the control system, are proprietary to the customer, are compact and lightweight and significantly reduce assembly time and expense for OEMs.

Strategy

Sun Hydraulics will continue to design, manufacture, market and support, on a worldwide basis, differentiated high-performance and high-quality products and systems. The Company believes this focus supports its business objectives of generating sustainable revenue growth that will consistently yield above-average returns on capital while achieving a high level of customer satisfaction. Key elements of the Company’s strategy include the following:

Deliver Value Through High-Quality, High-Performance Products. The Company’s products are designed with operating and performance characteristics that exceed those of many functionally similar products. The Company’s products provide high value because they generally operate more reliably and at higher flow rates and pressures than competitive offerings of the same size.

Achieve a High Level of Customer Satisfaction. Sun Hydraulics schedules orders to the customer’s request date. The Company believes that its long-term success is dependent upon its reputation in the marketplace, which in turn is a result of its ability to service its customers. The Company tests 100% of its screw-in cartridge valves to ensure the highest level of performance on a consistent basis.

Offer a Wide Variety of Standard Products. Sun Hydraulics offers the most comprehensive ranges of screw-in cartridge valves and manifolds in the world. The Company’s products contain a high degree of common content to minimize work in process and maximize manufacturing efficiency. Products are designed for use by a broad base of industries to minimize the risk of dependence on any single market segment or customer.

Expand the Product Line. New products are designed to complement existing products, having a synergistic effect. Where possible, new products use existing parts and generally fit into existing cavities. The Company will continue to develop new non-electrical and electrically actuated cartridges, including solenoid and proportional valves. The Company believes its electrically-actuated cartridge valves help to increase sales of the Company’s other cartridge valves and allow it to compete more effectively for integrated package business.

Capitalize on Integrated Package Opportunities. Sun Hydraulics designs and manufactures integrated packages which incorporate the Company’s screw-in cartridge valves. To support this effort, the Company is able to design and manufacture manifolds at its operations in Sarasota, Florida, and Kansas City, Kansas, USA, Coventry, England, Erkelenz, Germany, Seoul, Korea and at its operation in Shanghai, China. Some of the Company’s distributors also design and manufacture integrated packages which contain the Company’s screw-in cartridge valves. Sun Hydraulics encourages competitive manifold manufacturers to utilize the Company’s screw-in cartridge valves in their integrated package designs. The Company believes that customer requirements in the future will be for integrated packages more so than isolated components.

Expand Global Presence. Sun Hydraulics intends to continue to expand its global presence in the areas of distribution and international operations. The Company has strong distributor representation in most developed and developing markets, including North and South America, Western Europe, Asia, Australia, and South Africa. The Company will continue to expand its presence in key areas including, but not limited to, Eastern Europe, Russia, China and India. A strong local presence helps the Company compete for integrated package business, where proximity to the customer is beneficial.

3

Maintain a Horizontal Organization with Entrepreneurial Spirit. Sun Hydraulics believes that maintaining its horizontal management structure is critical to retaining key personnel and an important factor in attracting top talent. The Company believes this culture encourages communication, creativity, entrepreneurial spirit, and individual responsibility among employees, and has a large impact on operating results.

Leverage Manufacturing Capability and Know-how as Competitive Advantages. Sun Hydraulics believes its process expertise is a competitive advantage. The Company’s strong process capability is critical in achieving the high performance characteristics of its screw-in cartridge valves and integrated packages. The Company’s in-house heat-treatment capability, somewhat unique in the industry, is critical to the durability and differentiation of the Company’s cartridge valve products.

Sell Through Distributors. Due to the variety of potential customers and the Company’s desire to avoid overhead costs, the sales function is performed primarily by independent distributors. Many of the Company’s distributors sell products manufactured by other companies and act as system integrators by providing complete hydraulic systems to customers.

Develop Closer Relations with Key Customers. The Company maintains close relationships with some OEMs and end users of its products. These relationships help the Company understand and predict future marketplace needs and provide a venue to test and refine new product offerings. The Company recognizes it may sometimes be required to enter into direct transactional relationships to gain business with certain large OEMs. The Company will be selective in developing these relationships to avoid unnecessary bureaucracy and cost.

Form Strategic Relationships/Acquisitions. When it is deemed to be of strategic benefit, Sun Hydraulics may enter into various relationships with other manufacturers including, but not limited to, marketing, brand labeling and other non-exclusive or exclusive agreements. In the future the Company expects to expand its internally developed products and capabilities via investments in outside firms. These investments could be full acquisitions, joint ventures, partial ownership investments or other agreements.

Develop Complete Control System Solutions. Historically, the Company’s products have been purchased as components. Increasingly, the Company is engaged in developing complete integrated package system solutions that integrate more fully with OEMs’ machinery and expects future customer requirements will be in this area.

Products

Screw-in Hydraulic Cartridge Valves

Sun Hydraulics’ screw-in hydraulic cartridge valves are offered in five size ranges and include both electrically actuated and non-electrically actuated products. The floating construction pioneered by the Company results in a self alignment characteristic that provides performance and reliability advantages compared to most competitors’ product offerings. This floating construction differentiates the Company’s products from those of most of its competitors, who design and manufacture rigid screw-in cartridge valves that fit a common cavity. Some competitors manufacture certain products that fit the Company’s cavity.

Standard Manifolds

A manifold is a solid block of metal, usually aluminum or ductile iron, which is machined to create threaded cavities and channels into which screw-in cartridge valves can be installed and through which the hydraulic fluid flows.

The variety of standard manifolds offered by Sun Hydraulics is unmatched by any screw-in cartridge valve or manifold competitor. These products allow customers to easily integrate the Company’s screw-in cartridge valves into their machinery and equipment. Once designed, standard manifolds require minimal, if any, maintenance engineering over the life of the product and can be manufactured at each of the Company’s manufacturing operations.

4

Integrated Packages (using custom designed manifolds)

An integrated package consists of multiple cartridges assembled into a custom designed manifold for a specific customer to provide the specific operating characteristics of a customer’s circuit.

The advantages of Sun Hydraulics screw-in cartridge valves translate to integrated packages designed by the Company and result in products that are smaller in size with enhanced operating performance. Due to the self-alignment characteristic, the Company’s integrated packages do not routinely require testing once assembled, something often required when using competitive cartridge valves. Additionally, the Company has internally-developed, proprietary expert system software that it uses to manufacture custom manifolds efficiently in low volumes. Integrated packages provide many benefits to end users and equipment manufacturers, including reduced assembly time, order simplification, reduced leakage points, aesthetics, potentially fewer hose and fitting connections, and more control functions in a single location.

Engineering

Sun Hydraulics’ engineers play an important role in all aspects of the business, including design, manufacturing, sales, marketing and technical support. Engineers work within a disciplined set of design parameters that encourages the repeated incorporation of existing parts in new products. Engineers work closely with manufacturing personnel to define the processes required to manufacture products reliably and consistently.

Manufacturing

The Company is a process intensive manufacturing operation that makes extensive use of automated handling and assembly technology (including robotics) where possible to perform repetitive tasks, thus promoting manufacturing efficiencies and workplace safety. The Company is somewhat vertically integrated and has the capability to manufacture many of the parts that go into its products.

At its two Sarasota, Florida, manufacturing plants, the Company has extensive testing facilities that allow it to test fully all cartridge valve products. A metallurgist and complete metallurgical laboratory support the Company’s design engineers and in-house heat treatment.

The Company does not hold finished goods inventory but relies on its distributors to purchase and maintain sufficient inventory to meet customers’ demands. Most raw materials, including aluminum and steel, are delivered on a just-in-time basis. These and other raw materials are commercially available from multiple sources.

The Company controls most critical finishing processes in-house but relies on a small network of outside manufacturers to machine cartridge parts to varying degrees of completeness. Many high-volume machining operations are performed exclusively at outside suppliers. The Company is selective in establishing its supplier base and attempts to develop and maintain long-term relationships with suppliers.

The Company continually reviews all of its suppliers to improve the quality of incoming parts and to assess opportunities for better control of both price and quality. The Company’s quality systems at the U.S. and U.K. facilities are in compliance with ISO 9001:2000 for design and manufacture of steel cartridge valves, aluminum and ferrous manifolds for hydraulic systems. Those in Germany are certified to ISO 9001:2000 for the design, distribution and manufacturing of hydraulic components for mobile and industrial applications. Those in Korea are certified to ISO 9001:2000 and 14001:2004 for the design, development, production, and after sales service of hydraulic valves.

Sales and Marketing

Sun Hydraulics products are sold globally, primarily through independent fluid power distributors. Technical support is provided by each of the Company’s operations (Florida, Kansas, England, Germany, France, Korea, India and China).

The Company currently has 79 distributors, 55 of which are located outside the United States and a majority of which have strong technical backgrounds or capabilities, which enable them to develop practical, efficient, and cost-effective fluid power systems for their customers. In 2008, sales to the Company’s largest distributor represented less than 7% of net sales.

5

In addition to distributors, the Company sells directly to other companies within the hydraulic industry, including competitors, who incorporate the Company’s products into their hydraulic products or systems. The Company believes making it easy for other manufacturers to buy its products often offers them better alternatives than developing like products themselves.

The Company, to a limited degree, sells product directly to OEMs. Although the Company does not have any employee whose primary responsibility is direct sales, it may consider this in the future. The Company recognizes that to gain access to certain large OEM accounts it may have to deal directly with customers in the areas of sales and support.

The Company provides end users with technical information via its website and catalogues. This includes all information necessary to specify and obtain the Company’s products. The Company believes this approach helps stimulate demand for the Company’s products. The Company’s website is complete and easy to use with product information available 24 hours a day, seven days a week around the world.

Customers

Customers are broadly classified by being mobile or industrial.

Mobile applications involve equipment that generally is not fixed in place and is often operated in an uncontrolled environment, such as construction, agricultural, mining, and fire and rescue and other utility equipment. Mobile customers historically account for approximately two thirds of the Company’s net sales.

Industrial applications involve equipment that generally is fixed in place in a controlled environment. Examples include automation machinery, presses, plastics machinery such as injection molding equipment, and machine tools. Industrial applications historically account for approximately one third of the Company’s net sales.

In recent years, new applications have emerged that do not fit conveniently into the mobile or industrial categories, often blending requirements of each. Some of these applications include animatronics, wind power, wave power, solar power and amusement park rides. The Company expects its products to continue to be applied in areas outside of traditional mobile or industrial markets.

The Company does not warrant its products for use in any of the following applications, (i) any product that comes under the Federal Highway Safety Act, such as steering or braking systems for passenger-carrying vehicles or on-highway trucks, (ii) aircraft or space vehicles, (iii) ordnance equipment, (iv) life support equipment, and (v) any product that, when sold, would be subject to the rules and regulations of the United States Nuclear Regulatory Commission. These “application limitations” have alleviated the need for the Company to maintain the internal bureaucracy necessary to conduct business in these market segments.

Competition

The Company’s competitors include full-line producers and niche suppliers similar to the Company. Most competitors market globally. Full-line producers have the ability to provide total hydraulic systems to customers, including components functionally similar to those manufactured by Sun Hydraulics. The industry has experienced significant consolidation in recent years. Notably, large, full-line producers have acquired most of the independent screw-in hydraulic cartridge valve companies.

Most of the Company’s competitors produce screw-in cartridge valves that fit an industry common cavity that sometimes allows their products to be interchangeable. The industry common cavity is not currently supported by any national or global standards organizations, although there is an ongoing effort to standardize a modified version of this cavity in the United States. The International Standards Organization (ISO) has a standard screw-in cartridge cavity that is different from the industry common cavity, but the Company is not aware of any major competitor that currently produces a full line of standard products conforming to the ISO standard. The Company does not manufacture a product that fits either the industry common or the ISO standard cavity. Some competitors manufacture selected screw-in cartridge valves that fit the Company’s cavity. (see Risk Factors: The marketplace could adopt an industry standard cavity.)

6

The Company believes that it competes based upon the quality, reliability, price, value, speed of delivery and technological characteristics of its products and services.

Employees

As of December 27, 2008, Sun Hydraulics had 682 full-time employees in the United States, 75 in England, 36 in Germany, 3 in France and 42 in Korea. Over 90% of its employees are engaged in manufacturing, distribution, and engineering functions. No employees are represented by a union in any of the Company’s operating units, and management believes that relations with its employees are good. Employees are paid either hourly or with an annual salary at rates that are competitive with other companies in the industry and geographic areas in which they operate. Management believes that Sun Hydraulics’ culture, competitive salaries and wages, above average health and retirement plans, and a safe and pleasant working environment discourages employee turnover and encourages efficient, high-quality production. Nevertheless, due to the nature of the Company’s manufacturing business, it is sometimes difficult to attract skilled personnel. (see Risk Factors: Dependence on key employees and skilled personnel)

Patents and Trademarks

The Company believes that the growth of its business is dependent upon the quality and functional performance of its products and its relationship with the marketplace, rather than the extent of its patents and trademarks. The Company’s principal trademark is registered internationally in the following countries: Argentina, Australia, Brazil, Canada, Chile, China, France, Germany, India, Italy, Japan, Korea, Mexico, Peru, Spain, Sweden, Switzerland, the United Kingdom and the United States. While the Company believes that its patents have significant value, the loss of any single patent would not have a material adverse effect on the Company.

Available Information

The Company’s annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and amendments to those reports, as well as its proxy statements and other materials which are filed with or furnished to the Securities and Exchange Commission (“SEC”) are made available, free of charge, on or through the Sun Hydraulics website under the heading “Investor Relations—Reports—SEC Filings,” as soon as reasonably practicable after they are filed with, or furnished to, the SEC.

ITEM 1A.—RISK FACTORS

FACTORS INFLUENCING FUTURE RESULTS—FORWARD-LOOKING STATEMENTS

This Annual Report contains “forward-looking statements” (within the meaning of the Private Securities Litigation Reform Act of 1995) that are based on current expectations, estimates, forecasts, and projections about us, our beliefs, and assumptions made by us, including (i) our strategies regarding growth, including our intention to develop new products; (ii) our financing plans; (iii) trends affecting our financial condition or results of operations; (iv) our ability to continue to control costs and to meet our liquidity and other financing needs; (v) the declaration and payment of dividends; and (vi) our ability to respond to changes in customer demand domestically and internationally, including as a result of standardization. In addition, we may make other written or oral statements, which constitute forward-looking statements, from time to time. Words such as “may,” “expects,” “projects,” “anticipates,” “intends,” “plans,” “believes,” “seeks,” “estimates,” variations of such words, and similar expressions are intended to identify such forward-looking statements. Similarly, statements that describe our future plans, objectives or goals also are forward-looking statements. These statements are not guarantees of future performance and are subject to a number of risks and uncertainties, including those discussed below and elsewhere in this report. Our actual results may differ materially from what is expressed or forecasted in such forward-looking statements, and undue reliance should not be placed on such statements. All forward-looking statements are made as of the date hereof, and we undertake no obligation to update any forward-looking statements, whether as a result of new information, future events or otherwise.

Factors that could cause actual results to differ materially from what is expressed or forecasted in such forward-looking statements include, but are not limited to: (i) conditions in the capital markets, including the interest rate environment and the availability of capital; (ii) changes in the competitive marketplace

7

that could affect our revenue and/or cost bases, such as increased competition, lack of qualified engineering, marketing, management or other personnel, and increased labor and raw materials costs; (iii) new product introductions, product sales mix and the geographic mix of sales nationally and internationally; and the following risk factors:

Sales in our industry are subject to economic cycles. The capital goods industry in general, and the hydraulic industry in particular, are subject to economic cycles, which directly affect customer orders, lead times and sales volume. Economic downturns generally have a material adverse effect on our business and results of operations, as they did in 2001 through 2003 and they are now. Economic up cycles provide a context where demand for capital goods is stimulated, creating increased demand for the products we produce. In the future, continued weakening or improvement in the economy will directly affect orders and influence results of operations.

We are subject to intense competition. The hydraulic valve industry is intensely competitive, and competition comes from a large number of competitors, some of which are full-line producers and others that are niche suppliers like us. Full-line producers have the ability to provide total hydraulic systems to customers, including components functionally similar to those manufactured by us. We believe that we compete based upon quality, reliability, price, value, speed of delivery and technological characteristics. Many screw-in cartridge valve competitors are owned by corporations that are significantly larger and have greater financial resources than we have. We cannot assure that we will continue to be able to compete effectively with these companies.

Most competitors either manufacture manifolds or have sources that they use on a regular basis. In addition, there are many independent manifold suppliers that produce manifolds incorporating various manufacturers’ screw-in cartridge valves, including those made by us. Finally, there are many small, independent machine shops that produce manifolds at very competitive prices. We believe that competition in the manifold and integrated package business is based upon quality, price, performance, proximity to the customer and speed of delivery. Many competitors have very low overhead structures and we cannot assure that we will be able to continue to compete effectively with these companies.

In addition, we compete in the sale of hydraulic valves, manifolds and integrated packages with certain of our customers, who also may be competitors. Generally, these customers purchase cartridge valves from us to meet a specific need in a system that cannot be filled by any valve they make themselves. To the extent that we introduce new products in the future that increase competition with such customers, it may have an adverse effect on our relationships with them.

The marketplace could adopt an industry standard cavity that would not accommodate our products. Our screw-in cartridge valves fit into a unique cavity for which, to date, few other manufacturers have designed products. Accordingly, our screw-in cartridge valves are not interchangeable with those of other manufacturers. Most competitive manufacturers produce screw-in cartridge valves that fit into an industry common cavity. There is an ongoing effort in the United States to produce a new standard for screw-in hydraulic cartridge valve cavities based on the industry common cavity. Additionally, the International Standards Organization (“ISO”) has an existing industry standard for screw-in hydraulic cartridge valve cavities, which is different from our cavity and the industry common cavity. In our view, the industry common cavity, as well as the suggested standardized form of this cavity, and the ISO standard cavity, fail to address critical functional requirements, which could result in performance and safety problems of significant magnitude for end users. To our knowledge, no major competitor has converted its standard product line to fit the ISO standard cavity. Any move by a substantial number of screw-in cartridge valve and manifold manufacturers toward the adoption of ISO standard or another standard, based on the existing industry common cavity, could have a material adverse effect on our business, financial condition and results of operation. See “Item 1.—Business — Competition.”

We are subject to risks relating to international sales. In 2008, approximately 58% of our net sales were outside of the United States. For the past ten years, international sales have continued to represent a greater proportion of our consolidated sales. We will continue to expand the scope of operations outside the United States, both through direct investment and distribution, and expect that international sales will continue to account for a substantial portion of net sales in future periods. International sales are subject to various risks, including unexpected changes in regulatory requirements and tariffs, longer payment

8

cycles, difficulties in receivable collections, potentially adverse tax consequences, trade or currency restrictions, and, particularly in emerging economies, potential political and economic instability and regional conflicts. Furthermore, our international operations generate sales in a number of foreign currencies, particularly British pounds, the Euro, and the Korean Won. Therefore, our financial condition and results of operations can be affected by fluctuations in exchange rates between the United States dollar and these currencies. Any or all of these factors could have a material adverse effect on our business, financial condition and results of operations.

We are subject to various risks relating to our growth strategy. In pursuing our growth strategy, we intend to expand our presence in existing markets and enter new markets. In addition, we may pursue acquisitions and joint ventures to complement our business. Many of the expenses arising from expansion efforts may have a negative effect on operating results until such time, if at all, that these expenses are offset by increased revenues. We cannot assure that we will be able to improve our market share or profitability, recover our expenditures, or successfully implement our growth strategy. See “Item 1.—Business — Strategy.”

The expansion strategy also may require substantial capital investment for the construction of new facilities and their effective operation. We may finance the acquisition of additional assets using cash from operations, bank or institutional borrowings, or through the issuance of debt or equity securities. We cannot assure that we will be able to obtain financing from bank or institutional sources or through the equity or debt markets or that, if available, such financing will be on acceptable terms.

We are dependent upon key employees and skilled personnel. Our success depends, to some extent, upon a number of key individuals. The loss of the services of one or more of these individuals could have a material adverse effect on our business. Future operating results depend to a significant degree upon the continued contribution of key technical personnel and the skilled labor force. Competition for management and engineering personnel is intense and other employers may have greater financial and other resources. We conduct a substantial part of our operations in Sarasota, Florida. Continued success is dependent on the Company’s ability to attract and retain a skilled labor force at this location. There are no assurances that we will continue to be successful in attracting and retaining the personnel required to develop, manufacture and market our products and expand our operations. See “Item 1.—Business — Employees.”

We are subject to the risk of liability for defective products. The application of many of our products entails an inherent risk of product liability. We cannot assure you that we will not face any material product liability claims in the future or that the product liability insurance we maintain at such time will be adequate to cover such claims.

We are subject to fluctuations in the prices of raw materials. The primary raw materials used in the manufacture of our products are aluminum, ductile iron and steel. We cannot assure you that prices for such materials will not increase or, if they do, that we will be able to increase the prices for our products to maintain our profit margins. If future price increases do not adequately cover material cost increases, our operating results may be adversely affected.

We are dependent upon our parts suppliers. Our largest expense in cost of sales is purchased cartridge valve parts. We cannot assure you that our manufacturing costs and output would not be materially and adversely affected by operational or financial difficulties experienced by one or more of our suppliers.

Hurricanes could cause a disruption in our operations which could adversely affect our business, results of operations, and financial condition. A significant portion of our operations are located in Florida, a region that is susceptible to hurricanes. Such weather events can cause disruption to our operations and could have a material adverse effect on our overall results of operations. While we have property insurance to partially reimburse us for wind losses resulting from a named storm, such insurance would not cover all possible losses.

We are subject to the cost of environmental compliance and the risk of failing to comply with environmental laws. Our operations involve the handling and use of substances that are subject to federal, state and local environmental laws and regulations that impose limitations on the discharge of

9

pollutants into the soil, air and water and establish standards for their storage and disposal. We believe that our current operations are in substantial compliance with applicable environmental laws and regulations, the violation of which could have a material adverse effect on our business, financial condition and results of operations. New laws and regulations, or stricter interpretations of existing laws or regulations, could have a material adverse affect on our business, financial condition and results of operations. We have not suffered any material adverse effects due to compliance with environmental laws and regulations in the past.

Our board may decide to reduce or eliminate dividends. Although we have paid a cash dividend each quarter since our common stock began publicly trading in 1997, we cannot assure that funds will be available for this purpose in the future. The declaration and payment of dividends is subject to the sole discretion of our board of directors and will depend upon our profitability, financial condition, capital needs, acquisition opportunities, future prospects and other factors deemed relevant by the board, and may be restricted by the terms of our credit facilities.

Certain anti-takeover provisions may hinder or prevent a change in control. Our Articles of Incorporation provide for a classified board of directors. In addition, the Articles give the board of directors the authority, without further action by the shareholders, to issue and fix the rights and preferences of a new class, or classes, of preferred stock. These and other provisions of the Articles and our Bylaws may deter or delay changes in control, including transactions in which shareholders might otherwise receive a premium for their shares over then current market prices. In addition, these provisions may limit the ability of shareholders to approve transactions that they may deem to be in their best interests.

We are subject to control by certain shareholders and management. Christine L. Koski, the daughter of the deceased founder of the Company, Robert E. Koski, is a member of the board of directors. She, along with other family members, own or control approximately 29% of the outstanding shares of our common stock. Accordingly, the members of the Koski family have the ability to influence significantly the election of our directors and the outcome of certain corporate actions requiring shareholder approval, and to influence our business. Such influence could preclude any acquisition of the Company and could adversely affect the price of our common stock. Our directors and executive officers as a group beneficially own or control approximately 29% of the outstanding shares of our common stock.

ITEM 1B. UNRESOLVED STAFF COMMENTS

None.

ITEM 2. PROPERTIES

The Company owns major facilities in the United States, United Kingdom, Germany, and Korea, as set forth below.

The Company owns a 66,000 square foot facility in Sarasota, Florida, which houses manufacturing, design, marketing and other administrative functions. The Sarasota facility is well suited for the design, testing and manufacture of the Company’s products.

The Company also owns a 77,000 square foot manufacturing facility in Manatee County, Florida. The Manatee County facility, constructed in 1997, has a productive capacity similar to the Sarasota facility.

The close proximity of the Florida facilities allows for quick change and the ability to shift resources, including machinery and people, to effectively meet changing business requirements.

Both facilities in Florida are encumbered by a revolving line of credit, which matures on August 1, 2011. Monthly payment of interest only is due on the revolving line of credit, with a variable interest rate based upon the Company’s leverage ratio. At December 27, 2008, there was no outstanding balance on the line of credit.

10

The Company also owns 2 parcels of vacant land in Manatee County, Florida, for future expansion requirements. There is no mortgage on these properties and the Company believes the land to be well suited for additional manufacturing capacity.

The Company leases a 17,000 square foot manufacturing facility in Lenexa, Kansas, which is used to manufacture manifolds for the North American market.

The Company owns a 37,000 square foot facility in Coventry, England, free of any encumbrances. The facility, while primarily acting as a distributor, is also involved in cartridge assembly and manifold manufacturing.

The Company owns a 45,000 square foot distribution and manufacturing facility in Erkelenz, Germany, free of any encumbrances. This facility is well suited to house equipment used for manufacturing and testing of the Company’s products. Currently, a small portion of the manufacturing area is utilized and the remainder is leased on an annual basis to an outside company.

The Company owns a 10,000 square foot distribution and manufacturing facility in Inchon, Korea, free of any encumbrances.

The Company believes that its properties have been adequately maintained, are generally in good condition, and are suitable and adequate for its business as presently conducted. The extent of utilization of the Company’s properties varies from time to time and among its facilities.

ITEM 3. LEGAL PROCEEDINGS

The Company from time to time is involved in routine litigation incidental to the conduct of its business. The Company does not believe that any pending litigation will have a material adverse effect on its consolidated financial position or results of operations.

ITEM 4. SUBMISSION OF MATTERS TO A VOTE

OF SECURITY HOLDERS

There were no matters submitted to a vote of the security holders of the Company through the solicitation of proxies or otherwise during the fourth quarter of the fiscal year ended December 27, 2008.

11

PART II

ITEM 5. MARKET FOR REGISTRANT’S COMMON EQUITY,

RELATED STOCKHOLDER MATTERS AND

ISSUER PURCHASES OF EQUITY SECURITIES

Market Information

The Common Stock of the Company has been trading publicly under the symbol SNHY on the Nasdaq Global Select Market since the Company’s initial public offering on January 9, 1997. The following table sets forth the high and low closing sale prices of the Company’s Common Stock as reported by the Nasdaq Global Select Market and the dividends declared for the periods indicated. 2007 first quarter stock prices and dividend are adjusted for a three-for-two stock split, effected in the form of a 50% stock dividend, which became effective on July 15, 2007.

| High | Low | Dividends declared | |||||||

| 2008 |

|||||||||

| First quarter |

$ | 30.620 | $ | 19.130 | $ | 0.090 | |||

| Second quarter |

41.040 | 29.270 | 0.180 | ||||||

| Third quarter |

42.060 | 25.840 | 0.090 | ||||||

| Fourth quarter |

26.040 | 11.460 | 0.090 | ||||||

| 2007 |

|||||||||

| First quarter |

$ | 18.300 | $ | 13.307 | $ | 0.067 | |||

| Second quarter |

32.833 | 17.460 | 0.090 | ||||||

| Third quarter |

37.990 | 22.520 | 0.090 | ||||||

| Fourth quarter |

35.990 | 25.130 | 0.090 | ||||||

Holders

There were 116 shareholders of record of Common Stock on February 27, 2009. The number of record holders was determined from the records of the Company’s transfer agent and does not include beneficial owners of Common Stock whose shares are held in the names of securities brokers, dealers, and registered clearing agencies. The Company believes that there are approximately 12,000 beneficial owners of Common Stock.

Dividends

Quarterly dividends were paid on the 15th day of each month following the date of declaration. Additionally, the Company declared a special cash dividend of $0.09 per share to shareholders of record as of May 15, 2008, that was paid on May 30, 2008. The Company’s board of directors currently intends to continue to pay a quarterly dividend of at least $0.09 per share during 2009 and has announced a special cash dividend of $0.09 per share to shareholders of record as of March 15, 2009, payable on March 31, 2009. However, the declaration and payment of future dividends is subject to the sole discretion of the board of directors, and any determination as to the payment of future dividends will depend upon the Company’s profitability, financial condition, capital needs, acquisition opportunities, future prospects and other factors deemed pertinent by the board of directors.

Stock Split

On June 19, 2007, the Company declared a three-for-two stock split, effected in the form of a 50% stock dividend, to shareholders of record on June 30, 2007, which was paid on July 15, 2007. The Company issued approximately 5,500,000 shares of common stock as a result of the stock split. The effect of the stock split on outstanding shares, earnings per share and dividends per share has been retroactively applied to all periods presented.

12

On June 10, 2005, the Company declared a three-for-two stock split, effected in the form of a 50% stock dividend, to shareholders of record on June 30, 2005, payable on July 15, 2005. The Company issued approximately 3,600,000 shares of common stock as a result of the stock split. The effect of the stock split on outstanding shares, earnings per share and dividends per share has been retroactively applied to all periods presented.

Issuer Purchases of Equity Securities

The Company did not repurchase any of its stock during the fourth quarter of 2008.

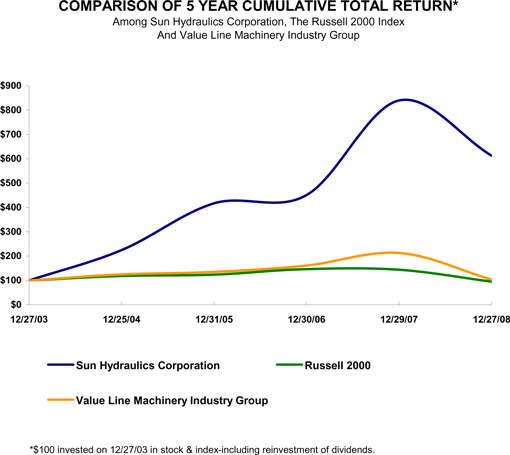

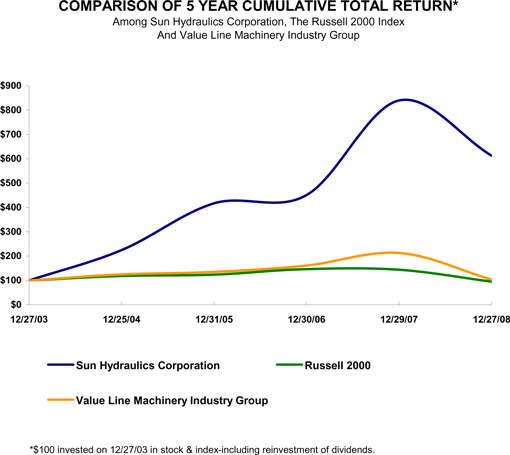

Five-Year Stock Performance Graph

The following graph compares cumulative total return among Sun Hydraulics Corporation, the Russell 2000 Index and the Value Line Machinery Industry Stock Index, from December 27, 2003, to December 27, 2008, assuming $100 invested in each on December 27, 2003. Total return assumes reinvestment of any dividends for all companies considered within the comparison. The stock price performance shown in the graph is not necessarily indicative of future price performance.

| 12/27/03 | 12/25/04 | 12/31/05 | 12/30/06 | 12/29/07 | 12/27/08 | |||||||

| Sun Hydraulics Corporation |

100.00 | 224.95 | 417.03 | 451.29 | 839.78 | 612.91 | ||||||

| Russell 2000 |

100.00 | 118.33 | 123.72 | 146.44 | 144.15 | 95.44 | ||||||

| Value Line Machinery Industry Group |

100.00 | 124.95 | 135.54 | 161.34 | 213.48 | 103.92 |

13

ITEM 6. SELECTED CONSOLIDATED FINANCIAL DATA

The following summary should be read in conjunction with the consolidated financial statements and related notes contained herein. See “Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations” and “Item 1. Business.”

The Company reports on a fiscal year that ends on the Saturday closest to December 31st. Each quarter generally consists of two 4-week periods and one 5-week period. As a result of the 2005 fiscal year ending December 31, 2005, the quarter ended April 2, 2005, consisted of one 4-week period and two 5-week periods, resulting in a 53-week year.

| Year Ended | |||||||||||||||

| Dec 27, 2008 | Dec 29, 2007 | Dec 30, 2006 | Dec 31, 2005 | Dec 25, 2004 | |||||||||||

| (in thousands except per share data) | |||||||||||||||

| Statement of Operations: |

|||||||||||||||

| Net sales |

$ | 178,278 | $ | 167,374 | $ | 142,282 | $ | 116,757 | $ | 94,503 | |||||

| Gross profit |

59,117 | 54,850 | 43,932 | 36,918 | 28,535 | ||||||||||

| Operating income |

36,377 | 33,635 | 25,051 | 19,180 | 12,294 | ||||||||||

| Income before income taxes |

37,729 | 34,371 | 24,903 | 19,137 | 11,732 | ||||||||||

| Net income |

$ | 25,735 | $ | 22,131 | $ | 16,223 | $ | 12,808 | $ | 7,830 | |||||

| Basic net income per common share |

$ | 1.55 | $ | 1.35 | $ | 0.99 | $ | 0.79 | $ | 0.51 | |||||

| Diluted net income per common share |

$ | 1.55 | $ | 1.34 | $ | 0.99 | $ | 0.78 | $ | 0.50 | |||||

| Dividends per common share |

$ | 0.45 | $ | 0.34 | $ | 0.27 | $ | 0.20 | $ | 0.10 | |||||

| Other Financial Data: |

|||||||||||||||

| Depreciation and amortization |

$ | 7,096 | $ | 6,341 | $ | 5,849 | $ | 5,604 | $ | 5,465 | |||||

| Capital expenditures |

10,874 | 12,591 | 9,525 | 8,813 | 4,987 | ||||||||||

| Balance Sheet Data: |

|||||||||||||||

| Cash and cash equivalents |

$ | 35,303 | $ | 19,337 | $ | 9,497 | $ | 5,830 | $ | 9,762 | |||||

| Working capital |

50,217 | 36,198 | 24,015 | 16,391 | 16,723 | ||||||||||

| Total assets |

122,385 | 110,780 | 87,185 | 73,561 | 71,808 | ||||||||||

| Total debt |

272 | 701 | 1,072 | 2,384 | 12,254 | ||||||||||

| Shareholders’ equity |

106,556 | 91,882 | 70,800 | 56,440 | 45,403 | ||||||||||

14

Quarterly Results of Operations

(unaudited, in thousands)

| For the Quarter Ended | ||||||||||||

| Dec 27, 2008 |

Sep 27, 2008 |

Jun 28, 2008 |

Mar 29, 2008 | |||||||||

| Net sales |

$ | 32,936 | $ | 44,771 | $ | 51,563 | $ | 49,008 | ||||

| Gross profit |

8,210 | 14,738 | 19,075 | 17,094 | ||||||||

| Operating income |

2,674 | 9,281 | 13,283 | 11,139 | ||||||||

| Income before income taxes |

3,154 | 9,768 | 13,341 | 11,465 | ||||||||

| Net income |

$ | 2,480 | $ | 6,657 | $ | 8,908 | $ | 7,690 | ||||

| Basic net income per common share |

$ | 0.15 | $ | 0.40 | $ | 0.54 | $ | 0.46 | ||||

| Diluted net income per common share |

$ | 0.15 | $ | 0.40 | $ | 0.54 | $ | 0.46 | ||||

| For the Quarter Ended | ||||||||||||

| Dec 29, 2007 |

Sep 29, 2007 |

Jun 30, 2007 |

Mar 31, 2007 | |||||||||

| Net sales |

$ | 41,289 | $ | 41,809 | $ | 43,422 | $ | 40,854 | ||||

| Gross profit |

13,346 | 13,324 | 14,297 | 13,883 | ||||||||

| Operating income |

8,064 | 8,045 | 8,859 | 8,667 | ||||||||

| Income before income taxes |

8,198 | 8,280 | 9,045 | 8,849 | ||||||||

| Net income |

$ | 5,127 | $ | 5,246 | $ | 5,952 | $ | 5,806 | ||||

| Basic net income per common share |

$ | 0.31 | $ | 0.32 | $ | 0.36 | $ | 0.35 | ||||

| Diluted net income per common share |

$ | 0.31 | $ | 0.32 | $ | 0.36 | $ | 0.35 | ||||

| For the Quarter Ended | ||||||||||||

| Dec 30, 2006 |

Sep 30, 2006 |

Jul 1, 2006 |

Apr 1, 2006 | |||||||||

| Net sales |

$ | 34,967 | $ | 36,202 | $ | 36,928 | $ | 34,185 | ||||

| Gross profit |

11,051 | 10,662 | 11,239 | 10,981 | ||||||||

| Operating income |

6,237 | 5,955 | 6,549 | 6,310 | ||||||||

| Income before income taxes |

6,253 | 5,896 | 6,501 | 6,253 | ||||||||

| Net income |

$ | 3,813 | $ | 3,916 | $ | 4,314 | $ | 4,180 | ||||

| Basic net income per common share |

$ | 0.23 | $ | 0.24 | $ | 0.26 | $ | 0.25 | ||||

| Diluted net income per common share |

$ | 0.23 | $ | 0.24 | $ | 0.26 | $ | 0.25 | ||||

15

ITEM 7. MANAGEMENT’S DISCUSSION AND ANALYSIS

OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS

OVERVIEW

Sun Hydraulics Corporation is a leading designer and manufacturer of high-performance screw-in hydraulic cartridge valves and manifolds, which control force, speed and motion as integral components in fluid power systems. The Company sells its products globally through wholly owned subsidiaries and independent distributors. Sales outside the United States for the year ended December 27, 2008, were approximately 58% of total net sales.

Approximately two thirds of product sales are used by the mobile market, which is characterized by applications where the equipment is not fixed in place, the operating environment is often unpredictable, and duty cycles are generally moderate to low. Some examples of the mobile market include equipment used in off-road construction, agriculture, fire and rescue, utilities, oil fields, and mining.

The remaining one third of sales are used by industrial markets, which are characterized by equipment that is fixed in place, typically in a controlled environment, and which operates at higher pressures and duty cycles. Power units, automation machinery, metal cutting machine tools and plastics machinery are some examples of industrial equipment. The Company sells to both markets with a single product line.

Industry Conditions

Demand for the Company’s products is dependent on demand for the capital goods into which the products are incorporated. The capital goods industries in general, and the fluid power industry specifically, are subject to economic cycles. According to the National Fluid Power Association (the fluid power industry’s trade association in the United States), the United States index of shipments of hydraulic products increased 8% and 1%, in 2008 and 2007, respectively.

The Company’s order trend has historically tracked closely to the United States Purchasing Managers Index (PMI). The index was 32.9 at the end of December 2008 compared to 48.4 at the end of December 2007. When the PMI is below 50, it indicates economic contraction. PMI remained relatively flat throughout most of 2008 before declining by nearly 12% in September compared to August. PMI continued to drop throughout the fourth quarter with December down over 33% compared to August PMI. PMI increased 8% in January 2009 compared to December 2008.

16

Results for the 2008 fiscal year

(Dollars in millions except net income per share)

| December 27, 2008 |

December 29, 2007 |

Increase | |||||||

| Twelve Months Ended |

|||||||||

| Net Sales |

$ | 178.3 | $ | 167.4 | 7 | % | |||

| Net Income |

$ | 25.7 | $ | 22.1 | 16 | % | |||

| Net Income per share: |

|||||||||

| Basic |

$ | 1.55 | $ | 1.35 | 15 | % | |||

| Diluted |

$ | 1.55 | $ | 1.34 | 16 | % | |||

| Three Months Ended |

|||||||||

| Net Sales |

$ | 32.9 | $ | 41.3 | -20 | % | |||

| Net Income |

$ | 2.5 | $ | 5.1 | -51 | % | |||

| Net Income per share: |

|||||||||

| Basic |

$ | 0.15 | $ | 0.31 | -52 | % | |||

| Diluted |

$ | 0.15 | $ | 0.31 | -52 | % | |||

The Company experienced another record year in 2008 with sales of $178.3 million, net income of $25.7 million, and cash flow from operations of $38.5 million.

Demand from the Company’s end markets was strong for the first three quarters of the year. Business began rapidly slowing in October. Because its book-to-ship cycle is so short, about four weeks, the Company began to feel the slowdown immediately. Fourth quarter sales to North America posted the smallest decline at 11%, Europe decreased 22%, and Asia was down 46%, resulting primarily from a drastic slowdown in Korea. Despite this slowdown, 2008 sales were still up 7% compared to 2007 and net income was up 16%. Current order levels in 2009 are as low as what we experienced at the end of 2003 and beginning of 2004.

Management is cognizant of the impact this recession has already had on the Company’s business and what a protracted global downturn will mean for its business levels going forward. The Company has already experienced the reduction of sales in December 2008 and, as evidenced by the forecast, this will extend throughout the first quarter of 2009. The reduced sales, coupled with the Company’s high fixed cost base, will ultimately result in a decrease in net income, which will exceed the decrease in sales. To address this decreased demand, the Company has eliminated overtime, frozen salaries for executives and key employees, intermittently shut down plants, and tightened discretionary spending.

For the past five years, the Company has benefited from a robust economic environment. The Company positioned itself to capitalize on this environment by having the appropriate products, services, and capacity to be able to satisfy our customers’ needs. The Company’s focus remains on preparation for the next growth cycle, developing new products, and enhancing productivity. During this period, the Company will not stop investing for future growth.

Maintaining the Company’s strong balance sheet and financial flexibility remains a key strategy. The Company ended 2008 with cash of $35.3 million, up $16.0 million from the previous year, an unused line of credit of $35.0 million, and less than half a million dollars of long-term debt. The Company continued to invest in its business in 2008 with capital expenditures for the year of approximately $10.9 million. The Company estimates capital expenditures in 2009 will be $7.0 million. The Company has ample cash to do the things management believes are necessary to position the Company to take the next step in its growth.

17

Dividends and Shared Distribution

The Company continues to share its success with both employees and shareholders. In May 2008, the Board introduced and declared its first shared distribution dividend. The shared distribution dividend rewards employees through a contribution into their retirement accounts and concurrently rewards shareholders with a special cash dividend. The Company declared a cash dividend of $0.09 per share, relating to the shared distribution, to shareholders of record as of May 15, 2008, that was paid on May 30, 2008. In addition to 6% of 2007 wages, U.S. employees received another 3% of wages in conjunction with the shared distribution dividend. The Company developed plans for international employees to participate in these shared distributions and they will receive their first contributions in 2009. Three percent of 2008 wages was accrued for international employees throughout 2008. The Company also declared its regular quarterly dividends of $0.09 per share for each quarter of 2008. These dividends were paid on the 15th day of each month following the date of declaration. Total dividends paid were $0.45 per share in 2008 for a total of $7.5 million.

In accordance with the Company’s performance for 2008, the board of directors felt it was appropriate to reward the Company’s employees for their diligent work and its shareholders for their support. This decision is consistent with Sun’s focus on long-term sustainable growth. The board of directors again declared a shared distribution dividend of $0.09 per share to shareholders of record on March 15, 2009, payable on March 31, 2009. Employees worldwide will receive 9% of their 2008 wages in accordance with the shared distribution, which amounts to approximately $3.0 million. The majority of employees will receive their shared distribution in the form of Company stock into qualified retirement accounts. The employee portion of the shared distribution reduced EPS for the fourth quarter and for the year by approximately $0.06 per share.

Outlook

The slowdown in business activity that began in October continued in the first two months of 2009. During this slowdown Sun has taken actions to reduce discretionary expenses while continuing to invest in people, processes, equipment, and product development. Sun’s 2009 first quarter sales are expected to be approximately $25.0 million with net income near breakeven. As in past business cycles, Sun’s investments throughout the business cycle directly translate into new business and increased market share as the economy recovers and that recovery in the business cycle often happens unannounced and at a rapid pace.

Results of Operations

The following table sets forth, for the periods indicated, certain items in the Company’s statements of operations as a percentage of net sales.

| For the Year Ended | |||||||||||||||

| Dec 27, 2008 | Dec 29, 2007 | Dec 30, 2006 | Dec 31, 2005 | Dec 25, 2004 | |||||||||||

| Net sales |

100.0 | % | 100.0 | % | 100.0 | % | 100.0 | % | 100.0 | % | |||||

| Gross profit |

33.2 | % | 32.8 | % | 30.9 | % | 31.6 | % | 30.2 | % | |||||

| Operating income |

20.4 | % | 20.1 | % | 17.6 | % | 16.4 | % | 13.0 | % | |||||

| Income before income taxes |

21.2 | % | 20.5 | % | 17.5 | % | 16.4 | % | 12.4 | % | |||||

18

Segment Information (in thousands)

| United States |

Korea | Germany | United Kingdom |

Elimination | Consolidated | ||||||||||||||

| 2008 |

|||||||||||||||||||

| Sales to unaffiliated customers |

$ | 111,180 | $ | 17,455 | $ | 27,356 | $ | 22,287 | $ | — | $ | 178,278 | |||||||

| Intercompany sales |

28,656 | — | 245 | 2,282 | (31,183 | ) | — | ||||||||||||

| Operating income |

24,531 | 1,148 | 7,693 | 3,231 | (226 | ) | 36,377 | ||||||||||||

| Total assets |

91,855 | 6,680 | 10,980 | 15,049 | (2,179 | ) | 122,385 | ||||||||||||

| Depreciation and amortization |

5,139 | 151 | 572 | 1,234 | 7,096 | ||||||||||||||

| Capital expenditures |

9,904 | 39 | 298 | 633 | 10,874 | ||||||||||||||

| 2007 |

|||||||||||||||||||

| Sales to unaffiliated customers |

$ | 99,516 | $ | 20,567 | $ | 24,164 | $ | 23,127 | $ | — | $ | 167,374 | |||||||

| Intercompany sales |

30,344 | — | 142 | 2,621 | (33,107 | ) | — | ||||||||||||

| Operating income |

22,408 | 2,103 | 5,955 | 3,205 | (36 | ) | 33,635 | ||||||||||||

| Total assets |

74,026 | 9,067 | 12,710 | 17,079 | (2,102 | ) | 110,780 | ||||||||||||

| Depreciation and amortization |

4,488 | 178 | 556 | 1,119 | 6,341 | ||||||||||||||

| Capital expenditures |

9,339 | 284 | 125 | 2,843 | 12,591 | ||||||||||||||

| 2006 |

|||||||||||||||||||

| Sales to unaffiliated customers |

$ | 89,077 | $ | 16,368 | $ | 19,128 | $ | 17,709 | $ | — | $ | 142,282 | |||||||

| Intercompany sales |

25,809 | — | 106 | 2,990 | (28,905 | ) | — | ||||||||||||

| Operating income |

16,608 | 2,212 | 4,046 | 2,330 | (145 | ) | 25,051 | ||||||||||||

| Total assets |

59,505 | 7,580 | 8,187 | 13,756 | (1,843 | ) | 87,185 | ||||||||||||

| Depreciation and amortization |

4,206 | 150 | 510 | 983 | 5,849 | ||||||||||||||

| Capital expenditures |

8,408 | 122 | 238 | 757 | 9,525 | ||||||||||||||

Comparison of Years Ended December 27, 2008 and December 29, 2007

Net Sales

Net sales were $178.3 million, an increase of $10.9 million, or 6.5%, compared to $167.4 million in 2007. Net sales increased 7.2% excluding the effect of exchange rates. The increase in net sales was primarily driven by increased demand in our end markets, which primarily include capital goods equipment. Price increases in 2008 accounted for approximately 1% of total sales. New product sales (defined as products introduced within the last five years) generally make up 15% of total sales.

North American sales increased 5.7% or $4.5 million, to $83.1 million in 2008, Asian sales increased 2.3% or $0.7 million, to $30.9 million in 2008, and European sales increased 9.2% or $5.0 million, to $59.3 million in 2008.

The U.S. reporting segment had sales of $111.2 million during 2008, up $11.7 million or 11.7%, compared to sales of $99.5 million during 2007. The increase was driven by demand in our end markets. International sales out of the U.S. were $37.1 million during 2008, up 26.6% or $7.8 million, compared to $29.3 million during 2007. Significant increases in sales were noted in Italy, China, and Australia.

The Korean reporting segment had sales of $17.5 million during 2008, down $3.1 million or 15.1%, compared to sales of $20.6 million during 2007. Currency effect reduced 2008 sales by approximately $2.0 million. The remaining decrease was related to a slowdown in sales to four major Korean customers that are in the construction equipment industry.

The German reporting segment had sales of $27.4 million during 2008, up $3.2 million or 13.2%, compared to sales of $24.2 million during 2007. Currency effect contributed approximately $2.1 million to sales in 2008. The remaining increase is primarily related to demand within Germany and in Austria.

The U.K. reporting segment had sales of $22.3 million during 2008, down $0.8 million or 3.6%, compared to sales of $23.1 million during 2007. Currency effect reduced 2008 sales by approximately $0.7 million, primarily related to sales in U.S. Dollars. The U.K experienced reduced sales within the U.K. and in Ireland, while increasing sales to Netherlands, Norway, and United Arab Emirates.

19

Gross Profit

Gross profit increased $4.3 million or 7.8% to $ 59.1 million in 2008, compared to $54.9 million in 2007. Gross profit as a percentage of net sales increased to 33.2% in 2008, compared to 32.8% in 2007. Margins were very strong in the first and second quarter of 2008, at 34.9% and 37.0%, respectively. The Company experienced some deterioration in the third quarter of 2008 when margins slipped to 32.9%. The sharp decline in 2008 fourth quarter sales resulted in gross margins of 24.9%. The Company has a large fixed cost base. This worked to its advantage over the last few years when the Company was able to leverage these fixed costs against consistently rising revenue. However, it has the opposite effect as the Company gets into periods of rapidly declining sales. The fixed costs remain, but cannot be absorbed as quickly by the lower revenue.

For 2008, the gross profit increases were primarily related to higher sales volume, which contributed $3.6 million of the increase. The remaining gains in gross profit were attributed to productivity improvements of approximately $0.8 million, primarily in the U.S. and U.K., and lower material costs of approximately $0.4 million, primarily in the U.S. and Europe. Decreases in overhead expenses as a percent of sales of approximately $1.2 million were offset by the increased retirement benefits primarily relating to the shared distributions of approximately $1.7 million.

Selling, Engineering, and Administrative Expenses

Selling, engineering and administrative expenses in 2008 were $22.7 million, a $1.5 million, or 7.2%, increase, compared to $21.2 million in 2007. The change is primarily a result of increases in compensation of $0.6 million, fringe benefit costs of $0.7 million, and professional fees of $0.2 million. The fringe benefits include an increase in retirement benefits primarily relating to the shared distributions of approximately $0.8 million. The increase in professional fees is related to additional tax services for the R&D tax credit study.

Operating Income

Operating income increased $2.7 million or 8.2% to $36.4 million in 2008, compared to $33.6 million in 2007, with operating margins of 20.4% and 20.1% for 2008 and 2007, respectively.

The U.S. reporting segment contributed $24.5 million to our consolidated operating income during 2008 compared to $22.4 million during 2007, an increase of $2.1 million. Record sales volume contributed $2.6 million to operating income. Additional increases resulted from decreased material costs, relating to redesign and resourcing of products, and productivity improvements. Increases in operating income were partially offset by increases in retirement benefits primarily relating to the shared distributions of approximately $1.8 million.

The Korean reporting segment contributed $1.1 million to our consolidated operating income during 2008 compared to $2.1 million during 2007, a decrease of $1.0 million. Reduction in sales resulted in a $0.3 million decrease in operating income. The remaining decrease resulted from increased material costs primarily related to the devaluation of the Korean Won against the U.S. Dollar for purchases made in U.S. Dollars.

The German reporting segment contributed $7.7 million to our consolidated operating income during 2008 compared to $6.0 million during 2007, an increase of $1.7 million. Record sales volume contributed $0.8 million to operating income. The remaining increase is primarily related to material costs due to the strength of the Euro against the U.S. Dollar for material purchases made in U.S. Dollars during the first nine months of the year. Increases in operating income were partially offset by the shared distributions of approximately $0.2 million.

The U.K. reporting segment contributed $3.2 million to our consolidated operating income during 2008 and 2007. The reduction in sales and shared distributions reduced operating income by approximately $0.5 million. These decreases were offset by gains in productivity and a reduction in fixed costs.

20

Interest Income, Net

Net Interest income for 2008 was $0.8 million compared to net interest income of $0.4 million for 2007. Total average debt for 2008, was $0.5 million compared to $0.9 million for 2007. Total average cash for 2008, was $27.3 million compared to $14.4 million for 2007. The Company did not have any outstanding variable debt during 2008.

Foreign Currency Transaction Gain, Net

Net foreign currency transaction gain was $0.5 million in 2008 compared to a minimal amount in 2007. While the Euro, the Korean Won and the British Pound weakened against the U.S. Dollar, the UK operations experienced gains related to sales conducted in U.S. dollars and from the revaluation of Sun Ltd. balance sheet items, which were held in U.S. dollars.

Miscellaneous Income, Net

Miscellaneous income was $0.1 million in 2008 compared to $0.3, million in 2007. The decrease is primarily related to a reduction in equity method investment earnings from the prior year. The current year income was primarily a result of proceeds from an insurance claim. This amount was partially offset by a loss on disposal of assets and charitable contributions.

Income Taxes

The provision for income taxes for the year ended December 27, 2008, was 31.8% of pretax income compared to 35.6% for the year ended December 29, 2007. The change was primarily due to the relative levels of income and different tax rates in effect among the countries in which the Company sells its products and the decrease in the German Statutory tax rate. The 2008 U.S. provision includes tax expense of $0.8 million related to the repatriation of cash from the German subsidiary and a tax benefit of $0.8 million for R&D tax credits for the years 2004 through 2007.

Comparison of Years Ended December 29, 2007 and December 30, 2006

Net Sales

Net sales were $167.4 million, an increase of $25.1 million, or 17.6%, compared to $142.3 million in 2006. Net sales increased 14.5% excluding the effect of exchange rates.

The increase was due in large part to the continued growth of international sales, particularly in Europe where sales increased 31.4%, or $13.0 million, to $54.3 million. Sales to France increased 27.0%, to Germany 30.5%, and to the U.K. 38.6%. Significant increases were also noted in Finland, Norway, Italy and Sweden.

Asian sales increased 28.5%, or $6.7 million, to $30.2 million. Domestic sales in Korea increased 25.7%, and sales to China increased 52.3%. A significant increase was also noted in Singapore.

North American sales increased 6.4%, or $4.7 million, to $78.7 million.

Gross Profit

Gross profit increased 24.9% to $54.9 million in 2007, compared to $43.9 million in 2006. Gross profit as a percentage of net sales increased to 32.8% in 2007, compared to 30.9% in 2006. Gross profit percentage increases were due to fixed cost absorption from higher sales volume, a sales price increase that occurred in July 2006, productivity improvements in the U.S. and improvements in selective material pricing on high volume purchased parts. Lower material costs in the U.K. and German operations due to the strength of local currencies against the U.S. dollar for material purchases made in U.S. dollars were also recognized.

21

Selling, Engineering, and Administrative Expenses

Selling, engineering and administrative expenses in 2007 were $21.2 million, a $2.3 million, or 12.4%, increase, compared to $18.9 million in 2006. The change is primarily a result of increased compensation expenses, which includes stock based compensation awards, advertising, and professional fees relating to tax, legal matters, and outside information technology services.

Interest (Income)/Expense, Net

Net Interest income for 2007 was $0.4 million compared to net interest expense of $0.1 million for 2006. Total average debt for 2007, was $0.9 million compared to $1.7 million for 2006. Total average cash for 2007, was $14.4 million compared to $7.7 million for 2006. The Company did not have any outstanding variable debt during 2007.

Foreign Currency Transaction (Gain)/Loss, Net

Foreign currency transaction gain was minimal in 2007, compared to a loss of $0.2 million in 2006. While the Euro, the Korean Won and the British Pound made gains against the U.S. dollar during the periods, the European operations experienced losses related to sales conducted in U.S. dollars and from the revaluation of Sun Ltd. balance sheet items, which were held in U.S. dollars.

Miscellaneous Income, Net

Miscellaneous income was $0.3 and $0.2, in 2007 and 2006, respectively. The increase was primarily a result of earnings from joint ventures.

Income Taxes

The provision for income taxes for the year ended December 29, 2007, was 35.6% of pretax income compared to 34.9% for the year ended December 30, 2006. The change was primarily due to the relative levels of income and different tax rates in effect among the countries in which the Company sells its products and an increase in the U.S. effective rate of approximately 1.3%. The increase was primarily a result of the phase-out of graduated rates and a change in permanent items, primarily related to the decreased benefit from joint venture earnings. These amounts were partially offset by the reversal of an unrecognized tax benefit during the period.

Liquidity and Capital Resources

Historically, the Company’s primary source of capital has been cash generated from operations, although short-term fluctuations in working capital requirements have been met through borrowings under revolving lines of credit as needed. The Company’s principal uses of cash have been to pay operating expenses, pay dividends to shareholders, make capital expenditures, and service debt.

Net cash flow from operations in 2008 was $38.5 million, compared to $28.2 million in 2007 and $19.6 million in 2006. The $10.3 million increase in the Company’s net cash flow from operations in 2008 was due primarily to the increase in net income of $3.6 million, and decreases in accounts receivable and inventory totaling $6.0 million compared to increases in the prior year totaling $4.5 million. Cash on hand increased $16.0 million from $19.3 million in 2007 to $35.3 million in 2008. Days sales outstanding decreased to 30 in 2008 from 38 in 2007 and inventory turns increased to 11.1 in 2008 from 9.9 in 2007. The decrease in days sales outstanding is primarily attributed to the steep decline in sales during the fourth quarter. The Company has not had, nor does it anticipate, any significant issues with collectability even in this difficult economic environment. As evidenced by the inventory turns, the Company has and continues to manage inventory levels, as it manufactures and ships product on a just in time basis. The increase in the Company’s net cash flow from operations in 2007, compared to 2006 was due primarily to the increase in net income of $5.9 million, and increases in accounts payable, and accrued expenses. In addition, the Company did not experience as much of an increase in inventory compared to the prior year.

Total capital expenditures for 2008 were $10.9 million. Capital expenditures, consisting primarily of purchases of machinery and equipment, were $8.4 million in 2008, compared to $12.6 million in 2007 and $9.5 million in 2006. Also included in capital expenditures for the year ended December 27, 2008, was the purchase of land for $2.5 million. Capital expenditures in 2009 are projected to be $7.0 million.

22